Rubber Roof Installers Caerdydd

Best EPDM Roof Installer in Caerdydd

Get multiple Rubber Roof Installers quotes for your project today! Compare profiles, reviews, accreditations, portfolio, etc... and choose the best offer.

Roofing Solutions (SW) LTD

4.845 reviewsBristol, GBRoofing Solutions SW Ltd is an established roofing and property maintenance contractor. We provide a complete roofing and home maintenance service in and around Bristol and the Westcountry for residential and commercial customers. We can handle all your roofing requirements from small roofing repairs to complete new roofs, flat roofs, windows doors, exterior painting and much more. Our skilled staff possesses extensive experience in the repair and installation of new roofs, roofing repairs, tiling, chimney refurbishment, flat roofing repairs, UPVC fascias, and guttering. All our work is carried out to the very highest standards and is backed up with a full guarantee for total peace of mind.

- Services

- Why Us?

- Testimonials

- Gallery

Get Quote

B L Roofing & Building Ebbw Vale Ltd

514 reviewsGBBL Roofing & Building is a premier roofing and building company serving Ebbw Vale and across South Wales. With over 20 years of experience, we pride ourselves on providing top-quality workmanship and reliable service. We understand that your home is your most valuable asset, and we are committed to delivering exceptional results for all your roofing and building needs. Our team of skilled professionals offers a comprehensive range of services, including general roofing, guttering, emergency roofing, fascia and soffits, felt roofs, flat roof repairs, leadwork, moss removal, industrial roofing, roof windows, storm damage repairs, and more. We also offer finance options and 24/7 emergency repairs to ensure your peace of mind. Why Choose Us? * Reliable and experienced team * 10+ year warranty on all work * Professional and high-quality finish * Free no-obligation quotes We are committed to providing our clients with exceptional service and exceeding their expectations. Contact us today for a free quote and let us take care of all your roofing and building requirements.

- Services

- Why Us?

- Our Team

- Testimonials

- Gallery

Get Quote

Roofers Cardiff

55 reviewsCardiff, Unit 39448, CF11 1NB, GBRoofers Cardiff is a specialist roofing company that provides services to both residential and commercial properties in Cardiff and the surrounding areas. Our company offers a range of services, including repair, and building of flat roofs, pitched roof repair, gutter repair and lead-work, fascias, soffits, and new build roofing.Our team of expert roofers have extensive experience across the Cardiff region, meaning our skills as a company also include battening, re-felting, tiling and slating. Additionally, our company can also provide PVC fascias and Velux window installation. Call us to get a free roofing quote for your property.Every member of our team works with high professionalism and enthusiasm to offer a reliable and trustworthy service that ensures customer satisfaction. We are your local roofing contractor that provides all types of roofing services and gutter services.

- Services

- Why Us?

- Gallery

Get Quote

Taunton Prestige Roofing

59 reviewsTaunton, TA1, GBWelcome to Taunton Prestige Roofing, your premier choice for expert roofing services across Taunton in the heart of Somerset. As a family-owned and operated business with decades of experience, we take immense pride in providing top-notch craftsmanship and unparalleled customer service to homeowners and businesses alike. Our team of skilled roofers provide dedicated roofing work to ensuring that your property is protected from the elements, and we go above and beyond to deliver results that exceed your expectations.We understand that your roof is more than just a shelter over your head – it’s an investment in the safety, comfort, and value of your property. That’s why we approach every project with meticulous attention to detail, using only the highest quality roofing materials and time-tested techniques to ensure a flawless finish. Whether you need roof repairs or a complete roof installation, our experts have the knowledge and expertise to get the job done right the first time.As a local roofing company deeply rooted in the Taunton community, we take great pride in serving our neighbours with honesty, integrity, and a commitment to excellence. We believe that building strong relationships with our clients is the key to our success, and we strive to earn your trust and confidence every step of the way. So, whether you’re dealing with a leaking roof, storm damage to the roof, or simply looking to upgrade your property’s curb appeal, you can count on Taunton Prestige Roofing to be your partner in protection.

- Services

- Why Us?

- Gallery

Get Quote

Duraseal Roofing

51 reviewsRhondda, GBDuraseal provide a large range of roofing services including roof design, construction, and repair services to domestic and commercial customers throughout South Wales. From new builds and house extensions to offices and factories, we can work on properties of all shapes and sizes. Our team work with a variety of materials and we’re known for our high quality work and professionalism. For more information on our services, give us a call today.

- Services

- Why Us?

- Testimonials

- Gallery

Get Quote

High Spec Roofing

4.88 reviewsThe Willows, Comeytrowe Lane, Taunton, TA1 5JD, GBHigh Spec Roofing offers premium roofing services across Taunton, Bridgwater, Wellington, and throughout Somerset. Our local contractors are available for all aspects of roofing including listed and heritage roofing, commercial projects, slating and tiling, flat roofing, general repairs, chimney restoration, as well as fascias, soffits, and guttering. We have 13 years of roofing experience and are fully trained local roofers. Our services are competitively priced, and we specialise in heritage buildings and commercial work. We offer a free consultation and quote for all our customers. Our team is based in Taunton and works alongside local contractors to ensure a premium service for each of our customers.

- Services

- Why Us?

- Our Team

- Testimonials

- Gallery

Get Quote- S

S Williams Roofing

51 reviews10010 Westheimer Rd, Suite 100, Houston, 77084, GBS. Williams Roofing is a family owned and operated roofing company serving the greater Houston area. We are fully licensed and insured and have been in business for over 20 years. We specialize in residential and commercial roofing, and we offer a wide range of services, including new roof installations, roof repairs, and roof maintenance. We are committed to providing our customers with the highest quality workmanship and customer service.

- Services

- Why Us?

- Gallery

Get Quote

D & R Roofing

4.58 reviewsAberdulais, Neath, Tithe Barn, SA10 8HL, GBBASED IN NEATH, ESTABLISHED IN 1995 EXPERTS IN ALL ASPECTS OF DOMESTIC AND COMMERCIAL ROOFING Professional Roofers serving Domestic and Commercial Clients across the west Glamorgan area. D&R Roofing was formed in 1995 and is a professional roofing company based in Neath and operating across the South Wales region. We offer our full range of roofing services to clients from the domestic and commercial sector and are large enough to cope with the largest of projects and often work for large national developers and Local Authorities. Domestic clients will also receive the same excellent level of customer service, attention to detail and exceptionally high standards of workmanship which has become our trademark and is the key factor in us receiving most of our work from word of mouth and personal recommendations from previous clients. We welcome all enquiries and offer free and friendly advice wherever we can, we don’t employ sales staff or use high pressure sales techniques we just offer professional, knowledgeable and honest advice. If you have an enquiry please do not hesitate to contact us and we will be pleased to discuss your requirements. What We Do New Roofs Roof Coverings Tiles & Slating Roof Repairs Chimneys Ridge Tiles Lead Work Fascias & Soffits Guttering Why Choose D&R Roofing? FULLY INSURED FAIR & COMPETITIVE RATES EXCELLENT WORKMANSHIP ALL WORK GUARANTEED FREE SURVEY & QUOTATION DOMESTIC & COMMERCIAL WORK ALL ROOF RREPAIRS & NEW BUILD

- Services

- Why Us?

- Our Team

- Testimonials

- Gallery

Get Quote

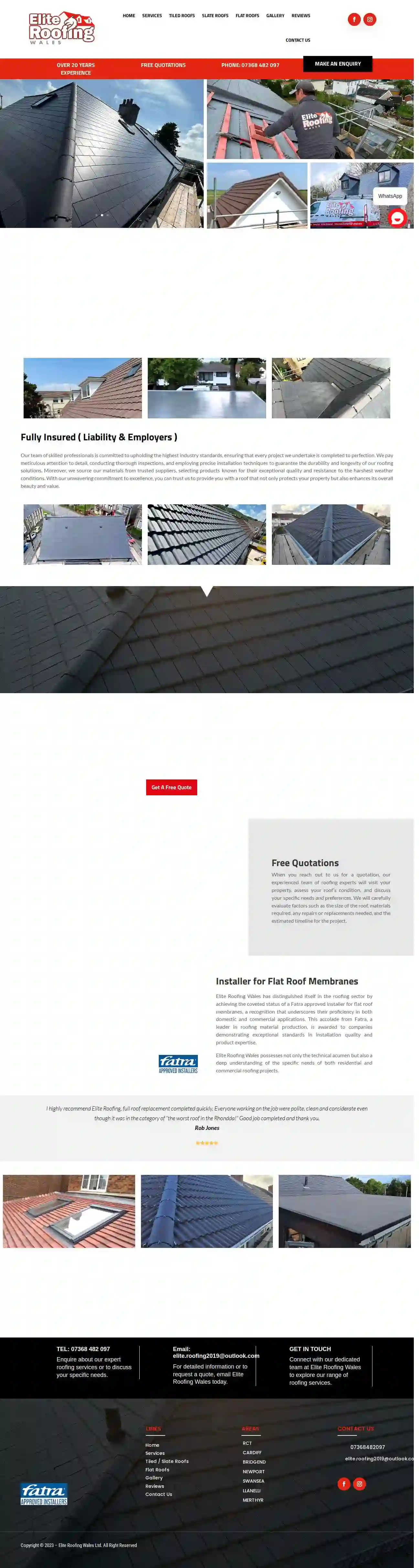

Elite Roofing Wales

4.912 reviewsGBElite Roofing Wales offers a range of exceptional roofing services in South Wales & the West, backed by years of experience in the industry. Our team has extensive knowledge and expertise in handling various roofing projects, catering to both residential and commercial properties. With a deep understanding of the unique weather conditions and architectural styles, we are well-equipped to provide tailored roofing solutions that withstand the test of time. Our experienced team is skilled in all aspects of roofing, including installation, repair, maintenance, and replacement. Whether you require a new roof installation for your home or need urgent repairs to fix leaks and damages, we have the expertise to deliver outstanding results.

- Services

- Why Us?

- Accreditations

- Our Team

- Testimonials

- Gallery

Get Quote

A L Henson Roofing

4.54 reviewsAberkenfig, Bridgend, Unit 1, The Business Centre, CF32 9ED, GBAt South Wales Roofing Network, our members are dedicated to providing a comprehensive range of roofing services across South Wales. We understand that your roof is a vital part of your home or business, offering protection and enhancing its aesthetic appeal. That's why we strive to deliver high-quality workmanship and exceptional customer service for all your roofing needs. Our team of experienced roofers can handle everything from minor repairs to complete roof replacements, ensuring your roof is in top condition. Whether you require flat roofing, pitched roofing, roof repairs, or fascias and soffits, our members have the expertise and knowledge to deliver outstanding results. We are committed to using durable and reliable materials, ensuring your roof withstands the test of time. Contact us today to discuss your roofing requirements and receive a free, no-obligation quote.

- Services

- Why Us?

- Accreditations

- Gallery

Get Quote

Over 12,314+ Roofing Contractors registered

Our roofing experts operate in Caerdydd and beyond!

Roofyng.co.uk has curated and vetted Top Roofing Companies in and around Caerdydd. Find a trustworthy business today.

Rubber Roof Installation FAQs

- Condition of the Existing Roof: The existing rubber roof should be in relatively good condition, with no significant damage or ponding water issues.

- Number of Layers: Most building codes allow only one layer of roof overlay. If your existing roof already has an overlay, a complete tear-off is usually required.

- Compatibility: Ensure the new EPDM membrane is compatible with the old one and that the adhesive will bond effectively to the existing surface.

- Local Building Codes: Check with your local building department to verify if roof overlays are permitted and if any specific requirements apply.

- Age: If your flat roof is nearing the end of its expected lifespan (15-30 years for most flat roofing systems), a replacement is usually a better investment than continual repairs.

- Extensive Damage: If the roof has experienced significant damage, such as widespread leaks, ponding water, or structural issues, replacement is often more cost-effective than trying to repair multiple problems.

- Recurring Leaks: If you've had multiple leaks that have been repaired but keep reappearing, it could indicate a systemic problem with the roofing system that warrants a replacement.

- Deteriorated Membrane: If the waterproofing membrane is showing signs of widespread deterioration, cracking, blistering, or alligatoring (a pattern of cracks resembling alligator skin), it's likely time for a replacement.

- Energy Efficiency: If your flat roof is poorly insulated, resulting in high energy bills, a replacement with a more energy-efficient roofing system could be a wise investment.

How do I find rubber roof installers in my area?

Can you put a new rubber roof over an old one?

What is a rubber roof?

How do I know if my flat roof needs replacing?

How do I find rubber roof installers in my area?

Can you put a new rubber roof over an old one?

- Condition of the Existing Roof: The existing rubber roof should be in relatively good condition, with no significant damage or ponding water issues.

- Number of Layers: Most building codes allow only one layer of roof overlay. If your existing roof already has an overlay, a complete tear-off is usually required.

- Compatibility: Ensure the new EPDM membrane is compatible with the old one and that the adhesive will bond effectively to the existing surface.

- Local Building Codes: Check with your local building department to verify if roof overlays are permitted and if any specific requirements apply.

What is a rubber roof?

How do I know if my flat roof needs replacing?

- Age: If your flat roof is nearing the end of its expected lifespan (15-30 years for most flat roofing systems), a replacement is usually a better investment than continual repairs.

- Extensive Damage: If the roof has experienced significant damage, such as widespread leaks, ponding water, or structural issues, replacement is often more cost-effective than trying to repair multiple problems.

- Recurring Leaks: If you've had multiple leaks that have been repaired but keep reappearing, it could indicate a systemic problem with the roofing system that warrants a replacement.

- Deteriorated Membrane: If the waterproofing membrane is showing signs of widespread deterioration, cracking, blistering, or alligatoring (a pattern of cracks resembling alligator skin), it's likely time for a replacement.

- Energy Efficiency: If your flat roof is poorly insulated, resulting in high energy bills, a replacement with a more energy-efficient roofing system could be a wise investment.